Introduction

Garbage compactor trucks play a crucial role in waste management by collecting and compacting trash efficiently. These specialized vehicles are a common sight on city streets, helping to keep our communities clean and hygienic. However, like any other heavy-duty machinery, garbage compactor trucks require regular maintenance to ensure they operate smoothly and efficiently. In this article, we will explore the importance of maintenance for garbage compactor trucks and provide a comprehensive guide on how to keep these vehicles in top condition with easy maintenance practices.

Importance of Maintenance for Garbage Compactor Trucks

Garbage compactor trucks are subjected to harsh operating conditions on a daily basis. They are constantly exposed to various types of waste materials, debris, and contaminants, which can take a toll on their mechanical components. Without proper maintenance, these trucks are at risk of breakdowns, malfunctions, and premature wear and tear. Regular maintenance is essential to prevent costly repairs, ensure optimal performance, and extend the lifespan of the vehicle.

Easy Maintenance Practices for Garbage Compactor Trucks

1. Regular Inspection and Cleaning

One of the simplest yet most effective maintenance practices for garbage compactor trucks is regular inspection and cleaning. Before and after each shift, operators should conduct a visual inspection of the vehicle to check for any signs of damage, leaks, or loose components. Any issues should be addressed promptly to prevent further damage. Additionally, the compactor body and hopper should be thoroughly cleaned after each use to remove debris and prevent corrosion.

2. Lubrication of Moving Parts

Proper lubrication is essential for the smooth operation of the mechanical components in a garbage compactor truck. Regularly lubricating moving parts such as hydraulic cylinders, hinges, and joints helps reduce friction, wear, and noise. Operators should follow the manufacturer's recommendations for the type and frequency of lubrication to ensure optimal performance and longevity of the components.

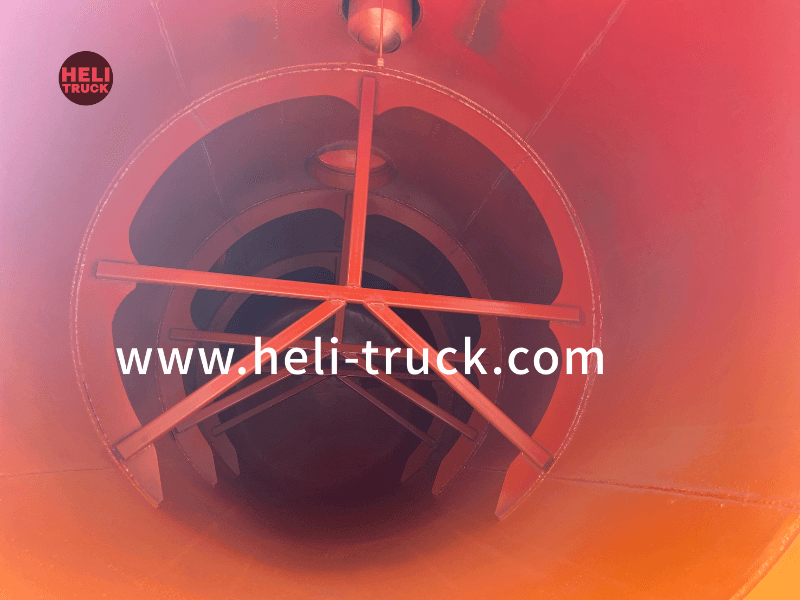

3. Check and Maintain Hydraulic System

The hydraulic system is a critical component of garbage compactor trucks, as it powers the compaction mechanism and other functions of the vehicle. Regularly checking the hydraulic fluid levels, filters, hoses, and connections is essential to prevent leaks, contamination, and system failures. Any issues with the hydraulic system should be addressed immediately by qualified technicians to avoid costly repairs and downtime.

4. Monitor Tire Pressure and Condition

Proper tire maintenance is crucial for the safety and efficiency of garbage compactor trucks. Operators should regularly check the tire pressure and tread depth to ensure they are within the recommended limits. Over or under-inflated tires can affect the vehicle's handling, fuel efficiency, and overall performance. Additionally, damaged or worn-out tires should be replaced promptly to prevent accidents and breakdowns.

5. Battery Maintenance

The battery is another critical component of garbage compactor trucks that requires regular maintenance. Operators should check the battery terminals, cables, and electrolyte levels regularly to ensure they are in good condition. Dirty or corroded terminals should be cleaned, and low electrolyte levels should be topped up with distilled water. Proper battery maintenance helps prevent starting problems and electrical issues.

6. Inspect and Replace Filters

Filters play a vital role in maintaining the cleanliness and efficiency of the engine, hydraulic system, and other components of garbage compactor trucks. Operators should regularly inspect and replace air, oil, fuel, and hydraulic filters according to the manufacturer's recommendations. Clogged or dirty filters can restrict airflow, reduce performance, and increase fuel consumption. Regular filter maintenance helps prolong the lifespan of the engine and other systems.

7. Train Operators on Proper Vehicle Use

In addition to regular maintenance practices, training operators on the proper use and care of garbage compactor trucks is essential for maximizing their lifespan and performance. Operators should be educated on safe driving practices, proper loading and unloading procedures, and how to identify and report any issues with the vehicle. By promoting a culture of preventive maintenance and responsible vehicle operation, fleet managers can minimize downtime and repair costs.

Conclusion

Garbage compactor trucks are indispensable assets in waste management operations, and proper maintenance is key to ensuring their reliability, efficiency, and longevity. By implementing https://www.heli-truck.com/feeding-efficiency-the-evolution-and-future-of-bulk-feed-trucks/ as regular inspection, lubrication, hydraulic system checks, tire maintenance, battery care, filter replacement, and operator training, fleet managers can keep their garbage compactor trucks in top condition with minimal effort. Investing time and resources in maintenance not only improves the performance of the vehicles but also reduces the risk of breakdowns, repairs, and costly downtime. By following the guidelines outlined in this article, fleet managers can create a proactive maintenance plan that promotes the longevity and efficiency of their garbage compactor trucks.